In the realm of plastic manufacturing, precision injection molding stands as a specialized technique that elevates the precision and quality of molded components to new heights. It is a meticulously controlled process that demands meticulous attention to detail, from material selection to tooling design to process parameters. While ordinary injection molding serves a broader range of applications, precision molding caters to those demanding the utmost precision and surface finish.

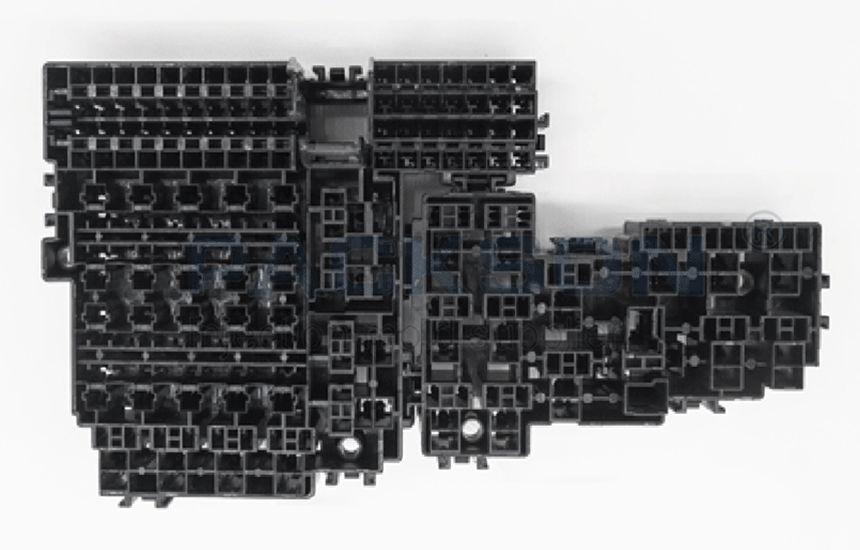

Precision injection molding is renowned for its ability to produce intricate and complex components with exceptional dimensional accuracy, often within micrometers. This remarkable precision enables the creation of precision mould parts with delicate features, tight tolerances, and smooth, flawless surfaces. Applications that fall under this umbrella include medical devices, aerospace components, precision optics, and intricate electronics.

High Precision: Dimensionally accurate components with tight tolerances down to micrometers.

Exceptional Surface Finish: Seamless and polished surfaces that meet the highest aesthetic standards.

Complex Designs: Ability to handle intricate and complex geometries with multiple features.

Strict Material Control: Careful selection and optimization of material properties for optimal performance.

Advanced Tooling: Highly precise molds engineered to ensure consistent and accurate part replication.

Ordinary injection molding, also known as conventional injection molding, is a widely used process for producing a wide range of plastic components. It offers a balance of precision, cost-effectiveness, and adaptability to various applications. Applications that typically utilize ordinary injection molding include consumer products, automotive components, packaging materials, and general-purpose parts.

While both precision and ordinary injection molding share the same fundamental principle of injecting molten plastic into a mold cavity, they differ in several key aspects:

Dimensional Accuracy: Precision injection molding excels in achieving tight tolerances, often within micrometers, while ordinary injection molding may have slightly looser tolerances.

Surface Finish: Precision molding prioritizes smooth, flawless surfaces, while ordinary molding may have some imperfections or surface roughness.

Design Complexity: Precision molding can handle complex geometries with intricate features, while ordinary molding may be limited in its ability to replicate complex designs.

Material Selection and Control: Precision molding demands careful selection and optimization of material properties to ensure optimal performance and dimensional stability. Ordinary molding offers more flexibility in material choices but may require stricter process control to achieve desired properties.

Tooling and Mold Design: Precision molding utilizes highly precise molds engineered to exacting standards, while ordinary molding employs molds that may not require the same level of precision.

Precision injection molding is the preferred choice when the following requirements are critical:

Extremely tight dimensional tolerances: Parts with dimensions measured in micrometers.

Exceptional surface finish: Components requiring ultra-smooth and flawless surfaces.

Complex geometries with intricate details: Parts with complex shapes and multiple features.

High performance and precision in critical applications: Medical devices, aerospace components, precision optics, and intricate electronics.

Ordinary injection molding is a cost-effective solution for a wide range of applications where precision is not the primary concern:

General-purpose components: Plastic parts for everyday use, such as packaging materials, toys, and consumer products.

Cost-sensitive applications: Parts where precision is not a major factor in design and performance.

Parts requiring flexibility in material selection: Applications where a wider range of materials can be accommodated.

Packson is a leading precision injection molding company with a proven track record of delivering high-quality components for demanding applications. Our team of experienced engineers and precision tooling specialists is committed to understanding your specific requirements and providing innovative solutions that meet your exact needs. We offer a comprehensive range of precision injection molding services, from design and prototyping to tooling fabrication and production. Contact us today to discuss your precision injection molding needs and experience the Packson difference.