As a company specialized in precision injection mold manufacturing, Packson-Mould is well aware of the critical role that precision machining plays in LSR (Liquid Silicone Rubber) molding. LSR molding is an advanced injection molding process that can produce high-quality, high-precision silicone rubber products. However, to achieve the precision and consistency required for LSR molding, precision machining technology is the key enabler.

Packson-Mould has advanced CNC machining equipment and strict quality control standards, and leverages precision machining in the following critical areas:

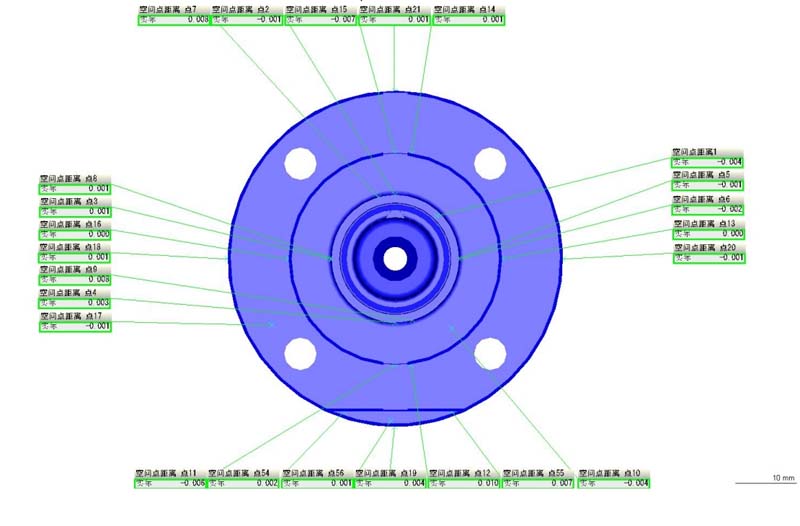

Mold Precision: The precision of LSR molds directly affects the quality of the final products. Packson-Mould ensures that the dimensions of mold cavities, runners, and other components reach micrometer-level accuracy, thereby guaranteeing the appearance, dimensions, and performance of the products.

Surface Finish: LSR products often require a high level of surface smoothness to meet the stringent requirements of medical, electronics, and other industries. Packson-Mould employs precise grinding and polishing techniques to achieve a highly flat and smooth mold surface, which is then transferred to the final product surface, enhancing the product's appearance quality.

Repeatability: Precision machining ensures a high degree of consistency across all mold components, allowing for stable product dimensions, appearance, and other characteristics from shot to shot. This is crucial for LSR products that require a high level of consistency.

Durability: Packson-Mould uses high-quality steel materials and precision machining processes, which not only ensure mold precision but also significantly extend the mold's service life. This not only reduces maintenance frequency and improves production efficiency, but also lowers manufacturing costs.

In summary, precision machining technology is the core enabler for Packson-Mould to provide high-quality LSR mold solutions for its customers. We will continue to invest in R&D and optimize our precision machining processes to create even greater value for our customers.