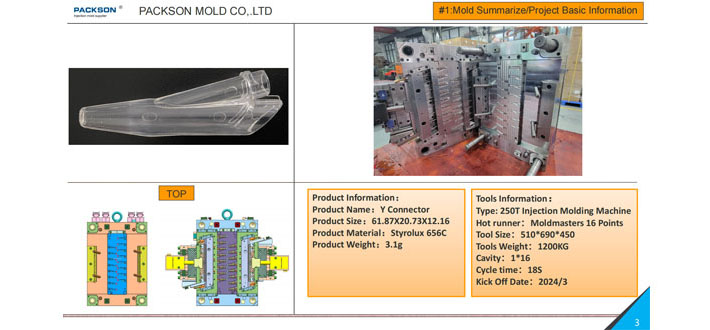

I am thrilled to share insights into our recently completed project involving a 16 cavities Y connector mold at Packson Mold. This project, which commenced production in 2025, showcases our commitment to innovation and efficiency in precision engineering.

The Y connector mold is a significant advancement in the medical sector, designed to meet the growing demand for high-quality components with rapid production cycles. Initially achieving a cycle time of 18 seconds, we have optimized the process to reach an impressive 16 to 17 seconds. This optimization not only boosts productivity but also ensures adherence to the rigorous standards required in medical applications.

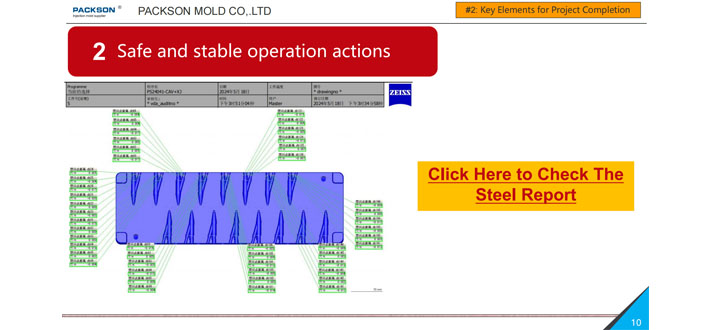

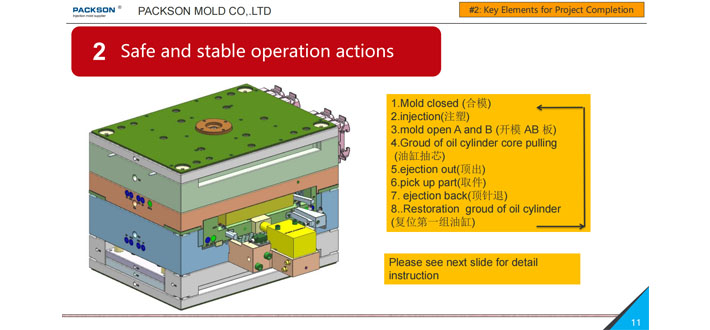

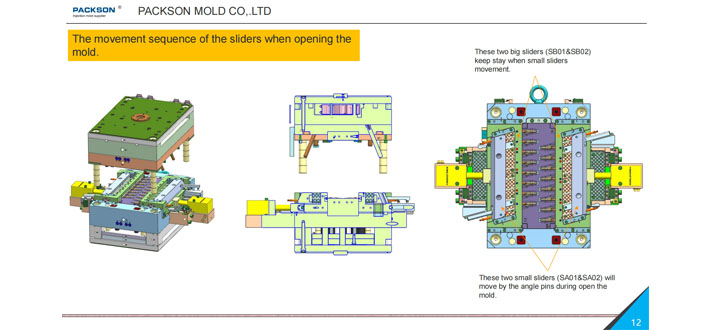

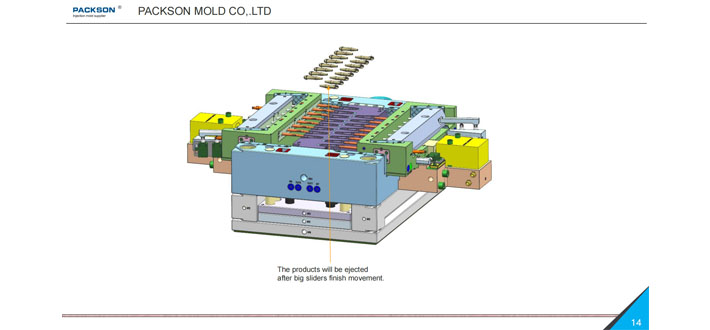

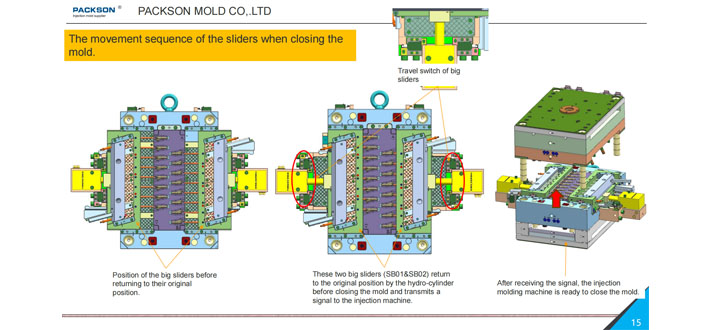

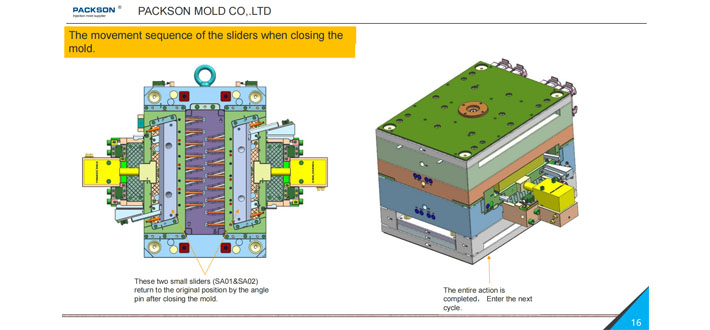

The mold features a sophisticated mechanism with small and big sliders operated by angle pins and hydro-cylinders, ensuring precise and efficient operation. This design minimizes downtime and maximizes output quality, which is critical in medical manufacturing.

We implemented strict project management controls to maintain production stability, ensuring all phases adhere to established timelines for timely delivery.

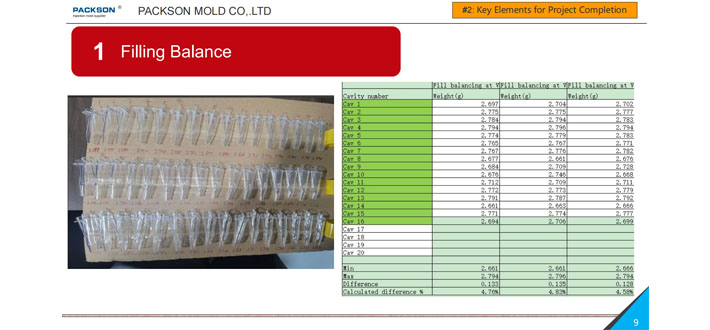

Focused on filling balance, safe operational actions, and constant temperature control, we enhanced production quality, crucial for maintaining the integrity of components in the medical field.

I am eager to explore potential collaboration opportunities. If you have new projects in the pipeline or are planning a visit to China, let's connect and discuss how we can work together for mutual success.