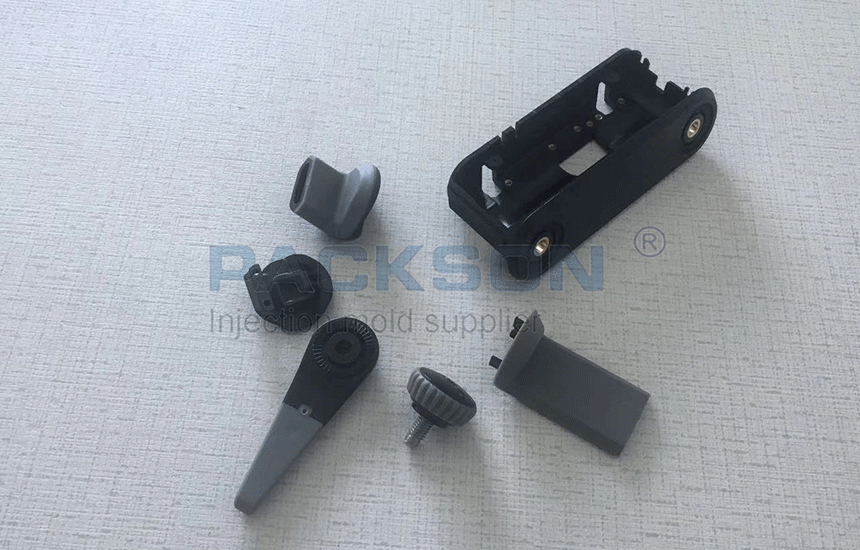

Production Process of Home Appliance Mold Parts

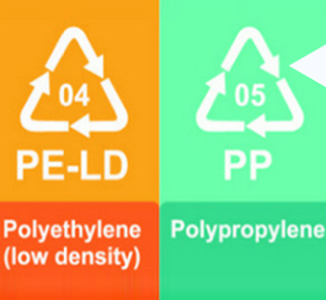

Packson is a plastic injection molding company with a history of over 15 years. We are a professional shooter for your electrical plastic molding solution. We offer a simple and seamless process for clients to convert their current design into production. Focusing on scientific molding solutions and quality control of production when it comes to the injection molding process. You can see below the process solution for the molding:

Before production, technicians will arrange color matching and mixing according to the specifications of the product. They will also make adjustments immediately once the result is not very good.

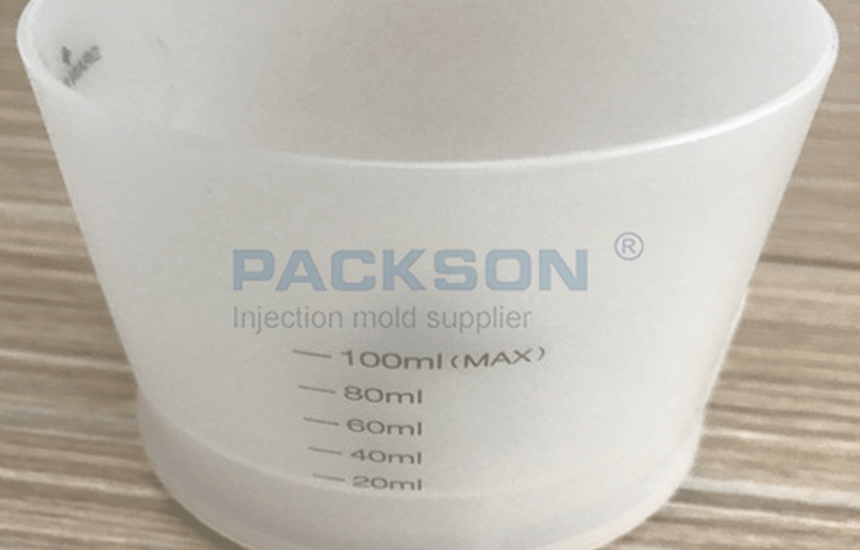

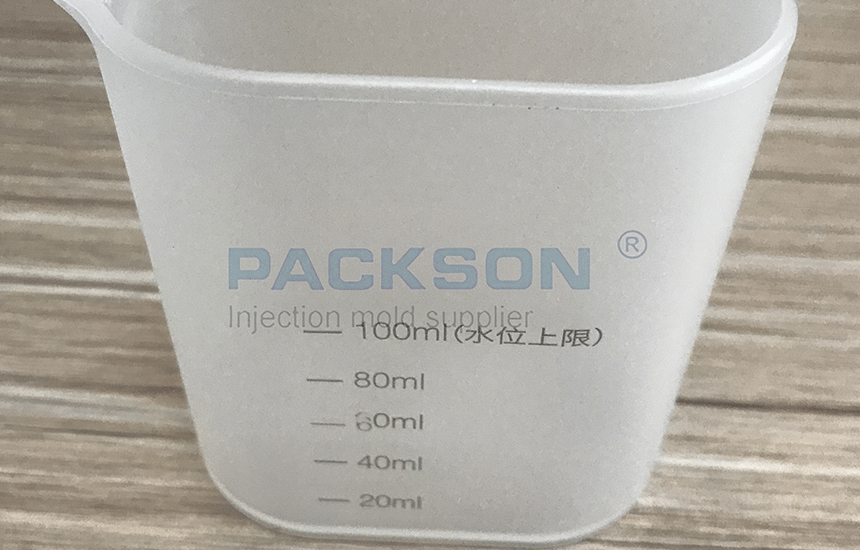

After we confirm all information of material specifications, the operator will make the first sample for quality worker checking.

During molding operation, the quality workers will go to a workshop for checking samples for the issues of appearance and audit tolerance at least 3 times.

After getting confirmation from the quality department, the operator will start to make the regular running of molding.

The quality control department starts to make dimension reports for the parts according to the issues like size, hardness, thickness, appearance, printing, burr, and other items.

After inspection, the production department will arrange to pack up the parts according to the customer's requirement.

Finally, the moulded parts will be shipped to the address where specified by the customer. For overseas delivery, we can work with you in a variety of ways like ocean shipment, air freight, and express delivery.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español